| Availability: | |

|---|---|

Details of machine

Branded Accessories

Performance and features

1. The machine adopts three-motor asynchronous servo speed, PLC control, and keeps running smoothly during acceleration

2. Automatic meter counting, alarm and other functions, using column alarm lights

3. Rewinding adopts A, B up and down differential shaft structure

4. Unwinding adopts CCD edge correction method

5. Flat knife slitting, waste edge blowing all over the discharge device

6. Integrated shaftless feeding, hydraulic lifting type, one magnetic powder unwinding.

Technical parameters

Machine type | 1300 type |

Mechanical maximum speed | 500 m/min |

Slitting thickness | 0.012mm-0.7mm (depending on different raw materials) |

Maximum rewinding diameter | Φ500mm |

Maximum diameter of unwinding | Φ800mm |

Maximum unwinding width for slitting raw materials | 50-1300mm |

Diameter of rewinding air shaft | φ75mm/2 pieces, Jiangsu. |

Slitting accuracy | ±0.2mm |

Total power | about 12kw |

Dimensions | 3600mm*1400mm*1950mm |

Weight | 3200kgs |

Color of machine | main white, optional black. |

Machine configuration

1.Unwinding part:

(1) The frame adopts steel plate structure

(2) Unwinding (1) 10 kg magnetic powder tension control

(3) Pneumatic lift up and down, motor move left and right, shaftless air cap, 3-inch/6-inch cone head

(4) CCD photoelectric correction system

(5) Magnetic powder brake + tension sensor + programmable controller to form a fully closed-loop tension control system, automatic constant tension control for unwinding

2.Traction part:

(1) Spindle motor driven independently, synchronous belt drive

(2)Rigid and flexible double rollers, steel roller active, rubber roller passive, rubber roller pneumatic clutch, pressure manual adjustment

(3) Automatic meter-fixed length, material-cut stop, remaining material control functions

3.Slitter part

(1) Slitting structure: flat knife + grooved roller

(2) Number of tool holders: 10 pcs

(3) Side material treatment: edge blowing machine + edge finishing machine to collect waste

4.Rewinding device

(1) Side wall type winding and unloading mechanism, equipped with unloading rack, 3-inch slip shaft

(2) Spindle servo motor independent drive

(3) Pneumatic precision pressure regulating valve controls the receiving pressure roller

(4) Automatic taper control

5.System

Programmable logic controller (PLC) centralized control, humanized program design and mechanical design, touch screen to monitor various parameters and operating status.

6.Frame

The wall board is made of 45mm high-strength whole board, which has been tempered and processed by the machining center.

The main list of detailed configuration

NO. | Name | Model | Quantity | Brand/Origin |

1. | PLC System | AFPX-XH | 1 set | Panasonic (Japan) |

2. | EPC | BIANFU | 1 set | Bianfu (Sino-foreign joint venture brand) |

3. | Magnetic powder brake | 100Nm/10kg | 1 set | Weizheng (China) |

4. | Traction | 2.2KW | 1 set | Yaskawa (Japan) |

5. | Rewinding | 4KW | 2 sets | |

6. | Tension sensor | ZY-50Kg | 2 pcs | Sino-foreign joint venture brand |

7. | Touch screen | 10 inches | 1 pc | MGCS (Sino-foreign joint venture brand) |

8. | Cylinder + Electromagnetic valve | AirTAC | 1 set | Taiwan |

9. | Guide roller bearing | NSK/NTN | 1 set | Japan |

10. | Rewind guide roll | 3 inch slip shaft | 2 pcs | China |

11. | Rewinding and pressing device | 1 set of upper and lower shafts | 2 sets | China |

12. | Unloading rack | Standard type | 1 set | |

13. | Waste Edge collecting machine | Standard type | 1 set |

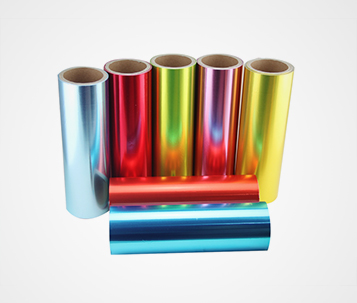

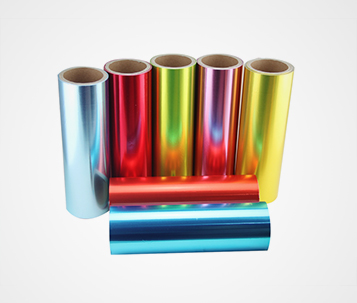

Application

This automatic slitting machine is suitable for slitting and rewinding of PET roll materials, such as BOPP, PET, PVC, paper-plastic composite and other roll materials.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Details of machine

Branded Accessories

Performance and features

1. The machine adopts three-motor asynchronous servo speed, PLC control, and keeps running smoothly during acceleration

2. Automatic meter counting, alarm and other functions, using column alarm lights

3. Rewinding adopts A, B up and down differential shaft structure

4. Unwinding adopts CCD edge correction method

5. Flat knife slitting, waste edge blowing all over the discharge device

6. Integrated shaftless feeding, hydraulic lifting type, one magnetic powder unwinding.

Technical parameters

Machine type | 1300 type |

Mechanical maximum speed | 500 m/min |

Slitting thickness | 0.012mm-0.7mm (depending on different raw materials) |

Maximum rewinding diameter | Φ500mm |

Maximum diameter of unwinding | Φ800mm |

Maximum unwinding width for slitting raw materials | 50-1300mm |

Diameter of rewinding air shaft | φ75mm/2 pieces, Jiangsu. |

Slitting accuracy | ±0.2mm |

Total power | about 12kw |

Dimensions | 3600mm*1400mm*1950mm |

Weight | 3200kgs |

Color of machine | main white, optional black. |

Machine configuration

1.Unwinding part:

(1) The frame adopts steel plate structure

(2) Unwinding (1) 10 kg magnetic powder tension control

(3) Pneumatic lift up and down, motor move left and right, shaftless air cap, 3-inch/6-inch cone head

(4) CCD photoelectric correction system

(5) Magnetic powder brake + tension sensor + programmable controller to form a fully closed-loop tension control system, automatic constant tension control for unwinding

2.Traction part:

(1) Spindle motor driven independently, synchronous belt drive

(2)Rigid and flexible double rollers, steel roller active, rubber roller passive, rubber roller pneumatic clutch, pressure manual adjustment

(3) Automatic meter-fixed length, material-cut stop, remaining material control functions

3.Slitter part

(1) Slitting structure: flat knife + grooved roller

(2) Number of tool holders: 10 pcs

(3) Side material treatment: edge blowing machine + edge finishing machine to collect waste

4.Rewinding device

(1) Side wall type winding and unloading mechanism, equipped with unloading rack, 3-inch slip shaft

(2) Spindle servo motor independent drive

(3) Pneumatic precision pressure regulating valve controls the receiving pressure roller

(4) Automatic taper control

5.System

Programmable logic controller (PLC) centralized control, humanized program design and mechanical design, touch screen to monitor various parameters and operating status.

6.Frame

The wall board is made of 45mm high-strength whole board, which has been tempered and processed by the machining center.

The main list of detailed configuration

NO. | Name | Model | Quantity | Brand/Origin |

1. | PLC System | AFPX-XH | 1 set | Panasonic (Japan) |

2. | EPC | BIANFU | 1 set | Bianfu (Sino-foreign joint venture brand) |

3. | Magnetic powder brake | 100Nm/10kg | 1 set | Weizheng (China) |

4. | Traction | 2.2KW | 1 set | Yaskawa (Japan) |

5. | Rewinding | 4KW | 2 sets | |

6. | Tension sensor | ZY-50Kg | 2 pcs | Sino-foreign joint venture brand |

7. | Touch screen | 10 inches | 1 pc | MGCS (Sino-foreign joint venture brand) |

8. | Cylinder + Electromagnetic valve | AirTAC | 1 set | Taiwan |

9. | Guide roller bearing | NSK/NTN | 1 set | Japan |

10. | Rewind guide roll | 3 inch slip shaft | 2 pcs | China |

11. | Rewinding and pressing device | 1 set of upper and lower shafts | 2 sets | China |

12. | Unloading rack | Standard type | 1 set | |

13. | Waste Edge collecting machine | Standard type | 1 set |

Application

This automatic slitting machine is suitable for slitting and rewinding of PET roll materials, such as BOPP, PET, PVC, paper-plastic composite and other roll materials.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...