| Availability: | |

|---|---|

Details of machine

waste edge device

Unloading rack

Unloading rack

electrical box

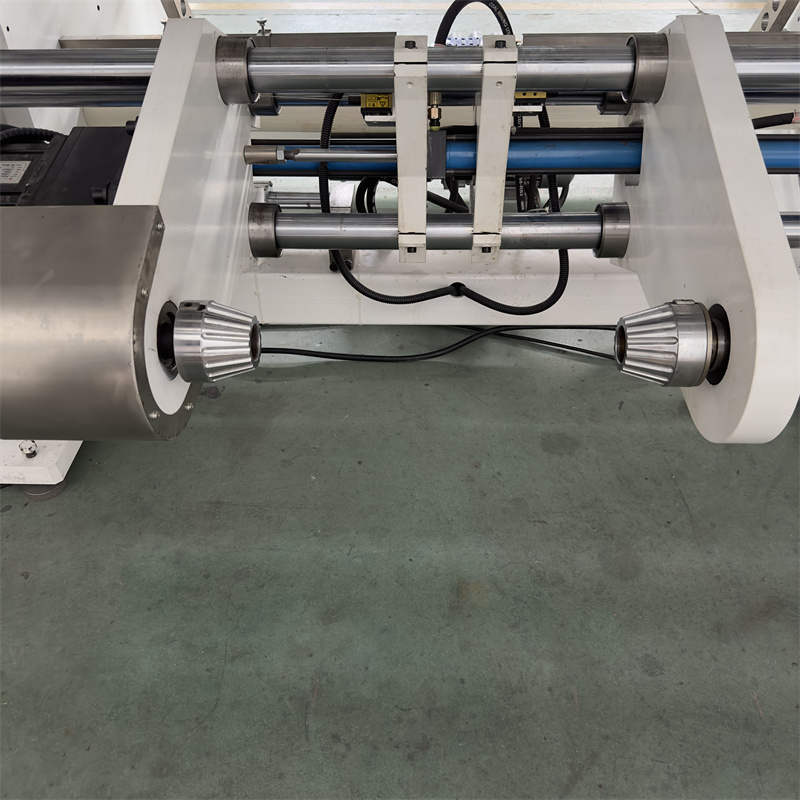

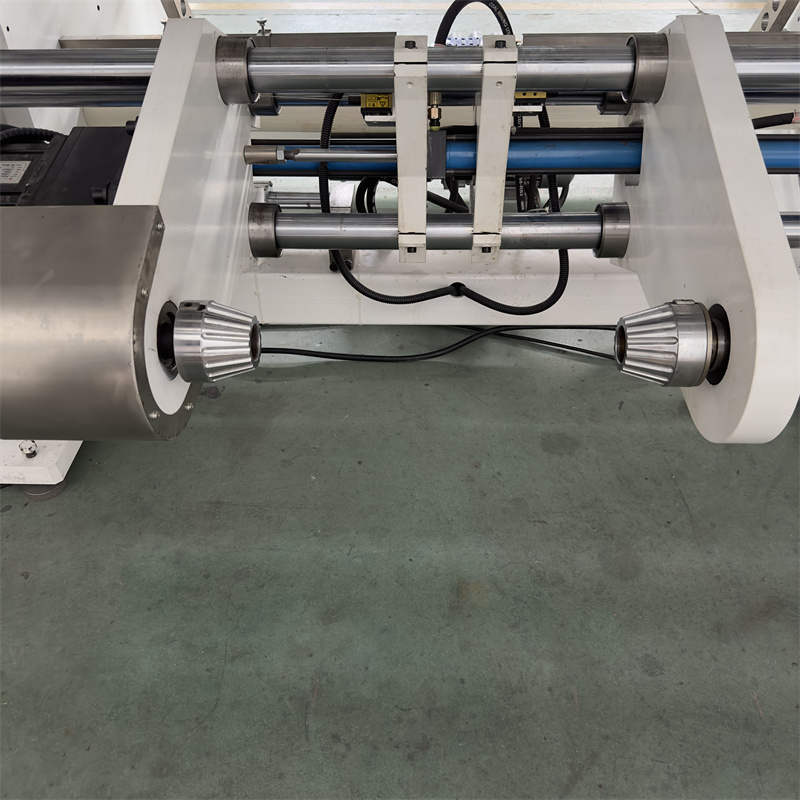

Differential shaft

SMC Precision pressure reducing valve

control switch area

Unloading shaft

Unloading rack

Unloading shaft

Touch screen

flat knife

Unwind arm remote control operation (patented structure)

SMC Precision pressure reducing valve

Shaftless gas cap structure

Laser positioning device

Double station EPC screen

electrical box details

Differential shaft and various shafts

electric cabinet (three motors)

Branded Accessories

Product Parameter

Items | Details |

Slitting thickness | 15~350g/m2 |

Max raw material unwinding dia. | φ1400mm |

Max raw material rewinding dia. | φ1000mm |

Max slitting width | 40-2000mm |

Rewinding air shaft dia. | φ74mm/ 2pcs |

Slitting precision | ±0.2mm |

Slitting speed | 50-300m/min |

Total power | 36kw |

Machine size | 4500×3200×1850mm |

Machine weight | 6000kg |

Product introduction

High speed slitting machine is a kind of mechanical equipment that cuts wide paper, mica tape or film into multiple narrow materials. It is often used in paper making machinery, wire and cable mica tape and printing and packaging machinery.

There are many advantages of this high speed slitting equipment:

Use servo three motor synchronize control, auto tape tension,center and surface rewinding together. Use frequency adjust speed, keep stable running when speed up.

Auto counter quantity, auto fixed length, auto machine stop when had alarm , auto tension control etc function. Feeding roll use air shaft use 3# (76mm paper tube core).

Rewinding use photocell control edge position control way. Circular knife slitting waste edge of roll, and it’s auto let out by fan. Automatic air shaft/ Hydraulic shaftness unwinding part.

Product features

I.The traction pressure roller is made of rubber, and after dynamic and static balance correction, the lifting of the traction pressure roller is controlled by pneumatics, and the pressure is adjustable.

II.The built-in length counting encoder rotates synchronously with the traction roller to accurately measure the length of the material, which has the advantages of high precision and high resolution. Considering the requirements of the production process, the program design has functions such as cumulative meter counting and automatic stop when the number is reached.

III.This machine adopts a high-performance variable frequency motor drive system, which is characterized by high precision, stable operation and convenient installation.

IV.The control system of this machine is centrally controlled by Japanese Panasonic PLC. According to the cutting process requirements, the parameters are set and the working status is monitored by the touch screen.

Applications

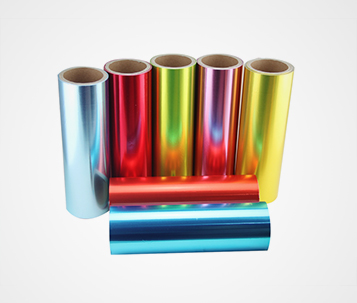

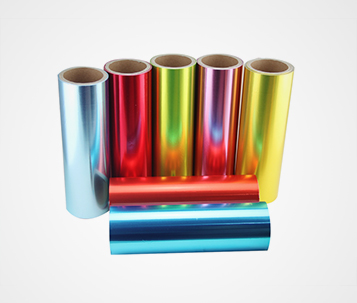

This automatic slitting machine is mainly used for: non-woven fabrics; mica tapes, paper, insulating materials and various film materials, especially suitable for narrow tapes (non-woven fabrics, paper, insulating materials, mica tapes, films, etc.) cut.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Details of machine

waste edge device

Unloading rack

Unloading rack

electrical box

Differential shaft

SMC Precision pressure reducing valve

control switch area

Unloading shaft

Unloading rack

Unloading shaft

Touch screen

flat knife

Unwind arm remote control operation (patented structure)

SMC Precision pressure reducing valve

Shaftless gas cap structure

Laser positioning device

Double station EPC screen

electrical box details

Differential shaft and various shafts

electric cabinet (three motors)

Branded Accessories

Product Parameter

Items | Details |

Slitting thickness | 15~350g/m2 |

Max raw material unwinding dia. | φ1400mm |

Max raw material rewinding dia. | φ1000mm |

Max slitting width | 40-2000mm |

Rewinding air shaft dia. | φ74mm/ 2pcs |

Slitting precision | ±0.2mm |

Slitting speed | 50-300m/min |

Total power | 36kw |

Machine size | 4500×3200×1850mm |

Machine weight | 6000kg |

Product introduction

High speed slitting machine is a kind of mechanical equipment that cuts wide paper, mica tape or film into multiple narrow materials. It is often used in paper making machinery, wire and cable mica tape and printing and packaging machinery.

There are many advantages of this high speed slitting equipment:

Use servo three motor synchronize control, auto tape tension,center and surface rewinding together. Use frequency adjust speed, keep stable running when speed up.

Auto counter quantity, auto fixed length, auto machine stop when had alarm , auto tension control etc function. Feeding roll use air shaft use 3# (76mm paper tube core).

Rewinding use photocell control edge position control way. Circular knife slitting waste edge of roll, and it’s auto let out by fan. Automatic air shaft/ Hydraulic shaftness unwinding part.

Product features

I.The traction pressure roller is made of rubber, and after dynamic and static balance correction, the lifting of the traction pressure roller is controlled by pneumatics, and the pressure is adjustable.

II.The built-in length counting encoder rotates synchronously with the traction roller to accurately measure the length of the material, which has the advantages of high precision and high resolution. Considering the requirements of the production process, the program design has functions such as cumulative meter counting and automatic stop when the number is reached.

III.This machine adopts a high-performance variable frequency motor drive system, which is characterized by high precision, stable operation and convenient installation.

IV.The control system of this machine is centrally controlled by Japanese Panasonic PLC. According to the cutting process requirements, the parameters are set and the working status is monitored by the touch screen.

Applications

This automatic slitting machine is mainly used for: non-woven fabrics; mica tapes, paper, insulating materials and various film materials, especially suitable for narrow tapes (non-woven fabrics, paper, insulating materials, mica tapes, films, etc.) cut.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...