| Availability: | |

|---|---|

Branded Accessories

Product Parameter

Items | Details |

Applicable Material | All kinds of flexible package materials |

Max.Mechanical speed | 450m/min |

Lamination width | 1300mm |

Max.Unwind & rewind Dia. | Ф1000mm |

Coating unit drive system | Controlled by independent servo |

Tension control | Dancing roller tension auto-control |

Product introduction

Solvent-less laminating machine is a kind of equipment that can be applied to solvent-less adhesive lamination. It uses solvent-less adhesives to laminate two or more materials together, also known as reactive lamination. It is an environmentally friendly and economical production technology for flexible packaging composites, which has significant advantages in economy, safety and environmental protection.

Translated with www.DeepL.com/Translator (free version)There are many advantages of solventless laminating machine:

Both unwinders are equipped with servo motors controlled by fully servo drives. With this technology quality and reliability of tension control is guaranteed in the entire range of tensions, regardless of the size of the reel and of the nature of the web.

Rewinder is also equipped with servo motor controlled by fully servo drive.

Digital tension control on unwinder and rewinder is achieved by processing the read out of low friction, short stroke, high resolution dancer rollers. In the tension control section between coating and lamination a set of load cells is involved.

Machine electronics automatically provide the proper regulation of tension in function of the value selected by the operator and the actual diameter of the reels. No additional operator adjustments are needed at the increase/decrease of the diameters.

Product features

I.Unwind and Rewind can rewind and unwind forward and backward with shaft-less and adopted the European imports of dc bus motion controller control, effectively guarantee the stability of the tension control and high precision.

II.The solvent-less lamination machine with high precision 5 roller coating method, and the high precision servo motor drive.

III.Equip with high precision chrome composite roll. Steel roller interior design spiral flow path for precise temperature control of the roller. And the design of imported pneumatic brake, can achieve rapid shutdown and tension. Independent cooling roller, which can effectively control the amount of deformation of the material to ensure the uniformity of rewinding.

IV.Through the low friction, short stroke and high spinning tension oscillating roller control so as to realize the digital tension control. The solvent-less lamination system can be set tension compared with actual tension, so as to automatically adjust the tension.

Applications

The scope of application of solventless lamination machine is very wide. It is environmentally friendly, hygienic and efficient, and it is especially suitable for the food and drug packaging industry. Composite substrates mainly include BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, aluminum foil, paper and so on.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

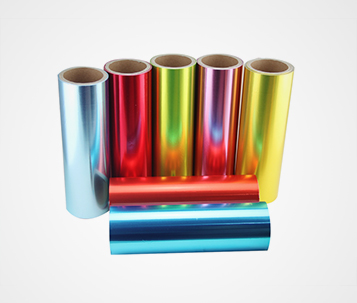

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Applicable Material | All kinds of flexible package materials |

Max.Mechanical speed | 450m/min |

Lamination width | 1300mm |

Max.Unwind & rewind Dia. | Ф1000mm |

Coating unit drive system | Controlled by independent servo |

Tension control | Dancing roller tension auto-control |

Product introduction

Solvent-less laminating machine is a kind of equipment that can be applied to solvent-less adhesive lamination. It uses solvent-less adhesives to laminate two or more materials together, also known as reactive lamination. It is an environmentally friendly and economical production technology for flexible packaging composites, which has significant advantages in economy, safety and environmental protection.

Translated with www.DeepL.com/Translator (free version)There are many advantages of solventless laminating machine:

Both unwinders are equipped with servo motors controlled by fully servo drives. With this technology quality and reliability of tension control is guaranteed in the entire range of tensions, regardless of the size of the reel and of the nature of the web.

Rewinder is also equipped with servo motor controlled by fully servo drive.

Digital tension control on unwinder and rewinder is achieved by processing the read out of low friction, short stroke, high resolution dancer rollers. In the tension control section between coating and lamination a set of load cells is involved.

Machine electronics automatically provide the proper regulation of tension in function of the value selected by the operator and the actual diameter of the reels. No additional operator adjustments are needed at the increase/decrease of the diameters.

Product features

I.Unwind and Rewind can rewind and unwind forward and backward with shaft-less and adopted the European imports of dc bus motion controller control, effectively guarantee the stability of the tension control and high precision.

II.The solvent-less lamination machine with high precision 5 roller coating method, and the high precision servo motor drive.

III.Equip with high precision chrome composite roll. Steel roller interior design spiral flow path for precise temperature control of the roller. And the design of imported pneumatic brake, can achieve rapid shutdown and tension. Independent cooling roller, which can effectively control the amount of deformation of the material to ensure the uniformity of rewinding.

IV.Through the low friction, short stroke and high spinning tension oscillating roller control so as to realize the digital tension control. The solvent-less lamination system can be set tension compared with actual tension, so as to automatically adjust the tension.

Applications

The scope of application of solventless lamination machine is very wide. It is environmentally friendly, hygienic and efficient, and it is especially suitable for the food and drug packaging industry. Composite substrates mainly include BOPP, PET, Nylon, CPP, PE, VMPET, VMCPP, PVC, aluminum foil, paper and so on.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

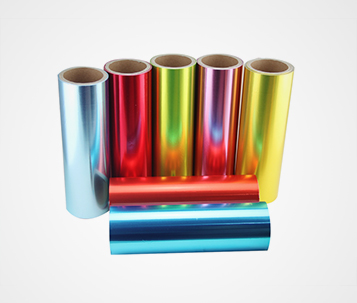

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...