| Availability: | |

|---|---|

Branded Accessories

Product Parameter

Items | Details |

Laminating width | 300-1100mm |

Mechanical speed | 150m/min |

First unwinding diameter | Ø1000mm |

Rewinding diameter | ø800mm |

Unwinding & winding shaft | air ejector pin + air shaft |

Gluing pressure | 350kg |

Drying method | electric heating |

Laminating pressure | 2000kg |

Total power | 65kw, 110kw (when electric heating) |

Dimensions | 11000×3500×3500mm |

Machine weight | 18000kg |

Product introduction

Our printing and laminating machine is used for different color printing of BOPP, PET, NY, CPP, CPE, aluminum foil, paper and other rolled film materials, and two-color printing and multi-layer coating to form a packaging material with excellent characteristics such as high strength, high freshness and resistance to steaming, etc.

There are many advantages of printing and laminating machine:

The whole machine adopts PLC programmable control and touch screen display operation.

The first unwinding adopts independent single-station rack, photoelectricity correction control, 20 kg magnetic powder brake control and automatic tension of pressure sensor.

The second unwinding adopts independent single-station rack, 20 kg magnetic powder brake control.

Product features

I.Seamless steel pipe tempering treatment is used for the plate roller shaft to ensure that the plate shaft has rigidity and no deformation. The embossing roller is of through-shaft structure, which can be replaced quickly. The embossing roller is pneumatic direct pressure type to ensure accuracy. The ink hopper is self-refluxing open, up and down can be manually adjusted. With curved helical gear drive, precise and durable.

II.Single color group independent drying system design, single group automatic constant temperature control, favorable to each color printing. Fully enclosed oven makes the heat source available for secondary use.

III.Coating method is anilox roller quantitative method, coating roller is integral structure. Pneumatic pressurized coating roller with adjustable pressure, coating roller is through-shaft type for quick replacement, two anti-fall cylinders, automatically locked when clutching. The squeegee device is of three-directional adjustment structure. The glue hopper is self-refluxing open type with manual adjustment up and down. Coating rollers are individually motor driven with high precision tension control. The feeding adjustment roller is bilateral adjustment. Overall rigid design of coating and glue roller with quick replacement function.

Applications

For simple printed composites, our printing and laminating machine can complete both printing and laminating processes in one go. Therefore, it is widely used in the flexible packaging industry, such as bags for daily necessities, labels, etc.

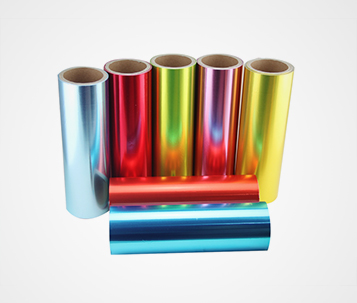

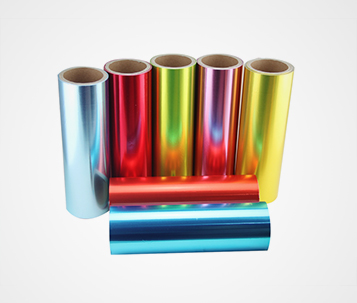

Here is some suitable materials and pictures forreference.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Laminating width | 300-1100mm |

Mechanical speed | 150m/min |

First unwinding diameter | Ø1000mm |

Rewinding diameter | ø800mm |

Unwinding & winding shaft | air ejector pin + air shaft |

Gluing pressure | 350kg |

Drying method | electric heating |

Laminating pressure | 2000kg |

Total power | 65kw, 110kw (when electric heating) |

Dimensions | 11000×3500×3500mm |

Machine weight | 18000kg |

Product introduction

Our printing and laminating machine is used for different color printing of BOPP, PET, NY, CPP, CPE, aluminum foil, paper and other rolled film materials, and two-color printing and multi-layer coating to form a packaging material with excellent characteristics such as high strength, high freshness and resistance to steaming, etc.

There are many advantages of printing and laminating machine:

The whole machine adopts PLC programmable control and touch screen display operation.

The first unwinding adopts independent single-station rack, photoelectricity correction control, 20 kg magnetic powder brake control and automatic tension of pressure sensor.

The second unwinding adopts independent single-station rack, 20 kg magnetic powder brake control.

Product features

I.Seamless steel pipe tempering treatment is used for the plate roller shaft to ensure that the plate shaft has rigidity and no deformation. The embossing roller is of through-shaft structure, which can be replaced quickly. The embossing roller is pneumatic direct pressure type to ensure accuracy. The ink hopper is self-refluxing open, up and down can be manually adjusted. With curved helical gear drive, precise and durable.

II.Single color group independent drying system design, single group automatic constant temperature control, favorable to each color printing. Fully enclosed oven makes the heat source available for secondary use.

III.Coating method is anilox roller quantitative method, coating roller is integral structure. Pneumatic pressurized coating roller with adjustable pressure, coating roller is through-shaft type for quick replacement, two anti-fall cylinders, automatically locked when clutching. The squeegee device is of three-directional adjustment structure. The glue hopper is self-refluxing open type with manual adjustment up and down. Coating rollers are individually motor driven with high precision tension control. The feeding adjustment roller is bilateral adjustment. Overall rigid design of coating and glue roller with quick replacement function.

Applications

For simple printed composites, our printing and laminating machine can complete both printing and laminating processes in one go. Therefore, it is widely used in the flexible packaging industry, such as bags for daily necessities, labels, etc.

Here is some suitable materials and pictures forreference.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...