| Availability: | |

|---|---|

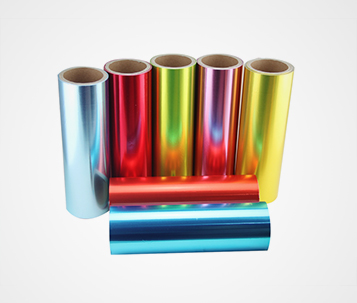

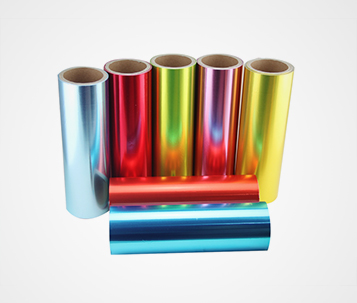

Branded Accessories

Product Parameter

Items | Details |

Laminating width | 400-1050mm |

Mechanical speed | 250m/min |

First unwinding diameter | ø600mm |

Second unwinding diameter | ø600mm |

Rewinding diameter | ø800mm |

Unwinding & winding shaft | air ejector pin + air shaft |

Gluing pressure | 350kg |

Drying method | Electric heating (steam, hot air, hot oil can be used according to customer requirements) |

Laminating pressure | 2000kg |

Total power | 138KW (when electric heating) |

Dimensions | 13000×4100×4000mm (when the top is opened) |

Machine weight | 20000kg |

Product introduction

Our lamination machine is used as a industrial laminating equipment to laminate two or more layers of rolled film materials such as film+film, film+aluminum foil and film+paper to form a packaging material with excellent characteristics such as high strength, high freshness and resistance to steaming.

There are many advantages of dry laminating machine:

It is suitable for laminating various substrate films, and it has higher freedom in substrate selection. Therefore it can produce laminated films with various properties such as heat resistance, oil resistance, barrier, chemical resistance, etc.

The final film is stronger, flatter and more rigid than extrusion laminated products.

It is easy to replace the raw materials and adhesives when it is laminating many varieties products with less quantity.

When it laminates polyethylene-based materials, it has no oxidation odor and better thermal stability.

Product features

I.Fast speed, 250 m/min, high efficiency. The double station does not stop the rewinding and unwinding, the output is large and the loss is small.

The output of the double station is more than double that of the single station. Not only ordinary PET, CPP, OPP, PE can be automatically spliced, but also aluminum foil, with stable tension.

II.It is especially suitable for aluminum foil laminating of electronic products, liquid packaging, washing supplies, etc., with obvious advantages.

III.Exquisite design, reasonable structure, high-grade configuration, durability and strong reliability (the service life is more than 10 years, and the accuracy can still be maintained) as follows:

① Two unwinding, one rewinding, all motor tension, automatic material change and cutting, high efficiency.

② The gluing part is equipped with an even-gluing unit, the coating is uniform, and the dot-shaped is changed to a flat glue layer, which improves the transparency of the product and does not produce dot-shaped bubbles or pores.

③ The oven is made of stainless steel, with negative pressure design, large air volume and high air pressure, and hot air reuse. It dries quickly and can also be laminated with water-based glue.

④ The laminating part is equipped with preheating roll, back pressure roll and cooling roll structure. The heat transfer oil is circulated outside, the surface temperature is uniform, the laminating pressure is uniform, and the laminating of materials can achieve a more perfect effect.

Applications

Our dry laminating machine can be applied to food packaging, drug packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Laminating width | 400-1050mm |

Mechanical speed | 250m/min |

First unwinding diameter | ø600mm |

Second unwinding diameter | ø600mm |

Rewinding diameter | ø800mm |

Unwinding & winding shaft | air ejector pin + air shaft |

Gluing pressure | 350kg |

Drying method | Electric heating (steam, hot air, hot oil can be used according to customer requirements) |

Laminating pressure | 2000kg |

Total power | 138KW (when electric heating) |

Dimensions | 13000×4100×4000mm (when the top is opened) |

Machine weight | 20000kg |

Product introduction

Our lamination machine is used as a industrial laminating equipment to laminate two or more layers of rolled film materials such as film+film, film+aluminum foil and film+paper to form a packaging material with excellent characteristics such as high strength, high freshness and resistance to steaming.

There are many advantages of dry laminating machine:

It is suitable for laminating various substrate films, and it has higher freedom in substrate selection. Therefore it can produce laminated films with various properties such as heat resistance, oil resistance, barrier, chemical resistance, etc.

The final film is stronger, flatter and more rigid than extrusion laminated products.

It is easy to replace the raw materials and adhesives when it is laminating many varieties products with less quantity.

When it laminates polyethylene-based materials, it has no oxidation odor and better thermal stability.

Product features

I.Fast speed, 250 m/min, high efficiency. The double station does not stop the rewinding and unwinding, the output is large and the loss is small.

The output of the double station is more than double that of the single station. Not only ordinary PET, CPP, OPP, PE can be automatically spliced, but also aluminum foil, with stable tension.

II.It is especially suitable for aluminum foil laminating of electronic products, liquid packaging, washing supplies, etc., with obvious advantages.

III.Exquisite design, reasonable structure, high-grade configuration, durability and strong reliability (the service life is more than 10 years, and the accuracy can still be maintained) as follows:

① Two unwinding, one rewinding, all motor tension, automatic material change and cutting, high efficiency.

② The gluing part is equipped with an even-gluing unit, the coating is uniform, and the dot-shaped is changed to a flat glue layer, which improves the transparency of the product and does not produce dot-shaped bubbles or pores.

③ The oven is made of stainless steel, with negative pressure design, large air volume and high air pressure, and hot air reuse. It dries quickly and can also be laminated with water-based glue.

④ The laminating part is equipped with preheating roll, back pressure roll and cooling roll structure. The heat transfer oil is circulated outside, the surface temperature is uniform, the laminating pressure is uniform, and the laminating of materials can achieve a more perfect effect.

Applications

Our dry laminating machine can be applied to food packaging, drug packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

Cellophane | 20-30um |

CPP | 20-60um |

Aluminum foil | 8-40um |

PET | 12-60um |

NY | 12-50um |

Lamination film | 15-60um |

BOPP | 20-60um |

PE | 30-100um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...