| Availability: | |

|---|---|

Branded Accessories

Product Parameter

Items | Details |

Max Width Of Material | 600mm/800mm/1000mm/1200mm/1400mm/1600mm |

Max Printing Speed | 10-50m/min / 10-100m/min |

Max Printing Width | 560mm/760mm/960mm/1160mm/1360mm/1560mm |

Thickness of Plate | 1.7mm/2.28mm/2.84mm/3.94mm |

Suitable material | Papers, plastic films, no-woven fabric, foils |

Machine weight | 4500kg/7500kg/8000kg/9000kg |

Printing color | 2/4/6/8 colors |

Machine dimension (L*W*H) | 5.3x1.9x3.0m/5.3x2.1x3.0m/5.3x2.3x3.0m |

Product introduction

Our stack type flexo printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

There are many advantages of automatic flexo printing machine:

The independent printing units are stacked on top of each other, arranged on one or both ends of the main wall panel of the printing press, or the printing units of various colors are installed on the rack.

Each printing unit is turned by gears mounted on the main wall panel. Stacked mimeographs can print 1-8 colors, but usually 6 colors.

Product features

The reason why the flexographic printing machine develops at a constant speed is that in addition to the technological breakthroughs in the sheet and ink, its own characteristics are an important reason for attracting users.

I.The machine has a simple structure, so it is easy to operate and easy to maintain. The price of a flexo press with the same function is about 30-50% of an offset or gravure press.

II.The causative material has strong adaptability, and satisfactory printing results can be obtained from 0.22mm plastic film to 10mm corrugated cardboard.

III.The embossing force is small, about 19.6-39.2N/square centimeter, especially for the printing of substrates such as corrugated paper that cannot withstand excessive pressure.

IV.The printing cost is low, mainly because the machine price is cheap, the plate making cost is low, the paper breakage rate during the printing process is low, and the production cost is 30-50% cheaper than the gravure printing.

V.The quality of the printed products is good. The use of anilox roller short ink path inking system not only simplifies the structure of the inking system, but also enables quantitative control of film thickness. The breakthrough in high-performance photosensitive resin plate technology has greatly improved the resolution of the printing plate and the reproducibility of the dots (up to 1-95%). Flexo printing can achieve 300 lines/in color level draft printing, and the printing effect is comparable to offset printing and gravure printing.

Applications

Due to the continuous increase in the range and types of printed products, the market of high speed flexo printing machines has gradually expanded. Trademark labels, plastic flexible packaging, woven bags, folding cartons and webs are the main products currently produced by flexo in the packaging printing market.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Max Width Of Material | 600mm/800mm/1000mm/1200mm/1400mm/1600mm |

Max Printing Speed | 10-50m/min / 10-100m/min |

Max Printing Width | 560mm/760mm/960mm/1160mm/1360mm/1560mm |

Thickness of Plate | 1.7mm/2.28mm/2.84mm/3.94mm |

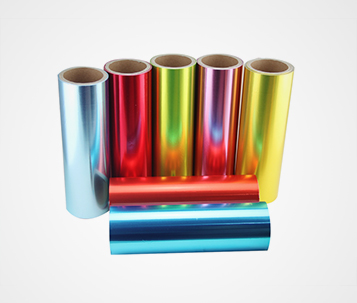

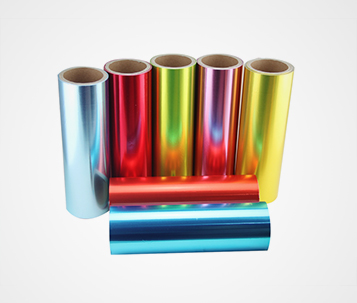

Suitable material | Papers, plastic films, no-woven fabric, foils |

Machine weight | 4500kg/7500kg/8000kg/9000kg |

Printing color | 2/4/6/8 colors |

Machine dimension (L*W*H) | 5.3x1.9x3.0m/5.3x2.1x3.0m/5.3x2.3x3.0m |

Product introduction

Our stack type flexo printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

There are many advantages of automatic flexo printing machine:

The independent printing units are stacked on top of each other, arranged on one or both ends of the main wall panel of the printing press, or the printing units of various colors are installed on the rack.

Each printing unit is turned by gears mounted on the main wall panel. Stacked mimeographs can print 1-8 colors, but usually 6 colors.

Product features

The reason why the flexographic printing machine develops at a constant speed is that in addition to the technological breakthroughs in the sheet and ink, its own characteristics are an important reason for attracting users.

I.The machine has a simple structure, so it is easy to operate and easy to maintain. The price of a flexo press with the same function is about 30-50% of an offset or gravure press.

II.The causative material has strong adaptability, and satisfactory printing results can be obtained from 0.22mm plastic film to 10mm corrugated cardboard.

III.The embossing force is small, about 19.6-39.2N/square centimeter, especially for the printing of substrates such as corrugated paper that cannot withstand excessive pressure.

IV.The printing cost is low, mainly because the machine price is cheap, the plate making cost is low, the paper breakage rate during the printing process is low, and the production cost is 30-50% cheaper than the gravure printing.

V.The quality of the printed products is good. The use of anilox roller short ink path inking system not only simplifies the structure of the inking system, but also enables quantitative control of film thickness. The breakthrough in high-performance photosensitive resin plate technology has greatly improved the resolution of the printing plate and the reproducibility of the dots (up to 1-95%). Flexo printing can achieve 300 lines/in color level draft printing, and the printing effect is comparable to offset printing and gravure printing.

Applications

Due to the continuous increase in the range and types of printed products, the market of high speed flexo printing machines has gradually expanded. Trademark labels, plastic flexible packaging, woven bags, folding cartons and webs are the main products currently produced by flexo in the packaging printing market.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...