| Availability: | |

|---|---|

Branded Accessories

Product Parameter

Items | Details |

Max Width Of Material | 600mm/800mm/1000mm/1200mm/1400mm/1600mm |

Max Printing Speed | 150m/min / 250m/min |

Max Printing Width | 560mm/760mm/960mm/1160mm/1360mm/1560mm |

Thickness of Plate | 1.7mm/2.28mm/2.84mm/3.94mm |

Suitable material | Papers, plastic films, no-woven fabric, foils |

Machine weight | 10000kg/11000kg/13000kg/16000kg/19000kg/21000kg |

Printing color | 4/6/8 colors |

Machine dimension (L*W*H) | 6.2x2x3.2m/6.2x2.2x3.2m/6.2x2.4x3.2m/6.2x2.6x3.2m/6.2x2.8x3.2m/6.2x3x3.2m |

Product introduction

Our ci flexo printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

There are many advantages of automatic flexo printing machine:

Because the web is tightly wrapped around the central impression cylinder, the tension is very stable, eliminating the need for an automatic register control system.

The structure is simple, the distance between the embossing points is short, and the registration is convenient. And the machine has good structural rigidity and stable performance.

The printing units are mounted between two wall panels around a common impression cylinder. The substrate is registered around a common impression cylinder.

Product features

Ci flexographic printing machine is popular by its own characteristics as followed:

I.Using soft polymer resin plate, compared with gravure printing, the plate-making cycle is shortened, and due to the improvement of plate manufacturing level and plate-making technology, it is sufficient to meet the needs of general packaging printing;

II.The anilox roller is used to transfer the ink. The anilox roller is both an ink transfer roller and an ink metering roller, which realizes the same short ink path as gravure, and can supply ink accurately according to the process requirements. For parts including anilox The optimization of the rollers precisely controls the ink color and thickness of the ink layer;

III.Zero pressure printing not only reduces the vibration and wear of the machine, but also reduces the wear of the plate, which is especially beneficial for the printing of soft materials. The power system is equipped with anti-vibration and vibration-absorbing devices. During transmission, it is transmitted through the synchronous belt of the main motor, which greatly reduces the vibration and noise of the machine running;

IV.Use water-based environmentally friendly ink to reduce pollution;

V.Because the web is tightly wrapped around the central impression cylinder, the tension is very stable.

Applications

In the European and American markets, as flexographic printing equipment, ci flexo printing machines account for about 70% of the entire flexo printing machine market, and most of them are used in flexible packaging printing, corrugated paper pre-printing and label printing.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Max Width Of Material | 600mm/800mm/1000mm/1200mm/1400mm/1600mm |

Max Printing Speed | 150m/min / 250m/min |

Max Printing Width | 560mm/760mm/960mm/1160mm/1360mm/1560mm |

Thickness of Plate | 1.7mm/2.28mm/2.84mm/3.94mm |

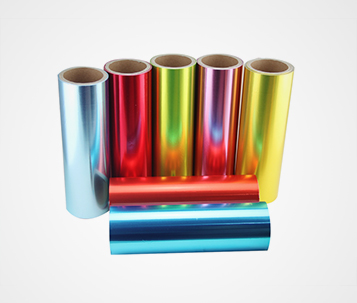

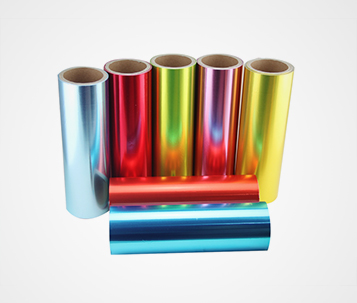

Suitable material | Papers, plastic films, no-woven fabric, foils |

Machine weight | 10000kg/11000kg/13000kg/16000kg/19000kg/21000kg |

Printing color | 4/6/8 colors |

Machine dimension (L*W*H) | 6.2x2x3.2m/6.2x2.2x3.2m/6.2x2.4x3.2m/6.2x2.6x3.2m/6.2x2.8x3.2m/6.2x3x3.2m |

Product introduction

Our ci flexo printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

There are many advantages of automatic flexo printing machine:

Because the web is tightly wrapped around the central impression cylinder, the tension is very stable, eliminating the need for an automatic register control system.

The structure is simple, the distance between the embossing points is short, and the registration is convenient. And the machine has good structural rigidity and stable performance.

The printing units are mounted between two wall panels around a common impression cylinder. The substrate is registered around a common impression cylinder.

Product features

Ci flexographic printing machine is popular by its own characteristics as followed:

I.Using soft polymer resin plate, compared with gravure printing, the plate-making cycle is shortened, and due to the improvement of plate manufacturing level and plate-making technology, it is sufficient to meet the needs of general packaging printing;

II.The anilox roller is used to transfer the ink. The anilox roller is both an ink transfer roller and an ink metering roller, which realizes the same short ink path as gravure, and can supply ink accurately according to the process requirements. For parts including anilox The optimization of the rollers precisely controls the ink color and thickness of the ink layer;

III.Zero pressure printing not only reduces the vibration and wear of the machine, but also reduces the wear of the plate, which is especially beneficial for the printing of soft materials. The power system is equipped with anti-vibration and vibration-absorbing devices. During transmission, it is transmitted through the synchronous belt of the main motor, which greatly reduces the vibration and noise of the machine running;

IV.Use water-based environmentally friendly ink to reduce pollution;

V.Because the web is tightly wrapped around the central impression cylinder, the tension is very stable.

Applications

In the European and American markets, as flexographic printing equipment, ci flexo printing machines account for about 70% of the entire flexo printing machine market, and most of them are used in flexible packaging printing, corrugated paper pre-printing and label printing.

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...