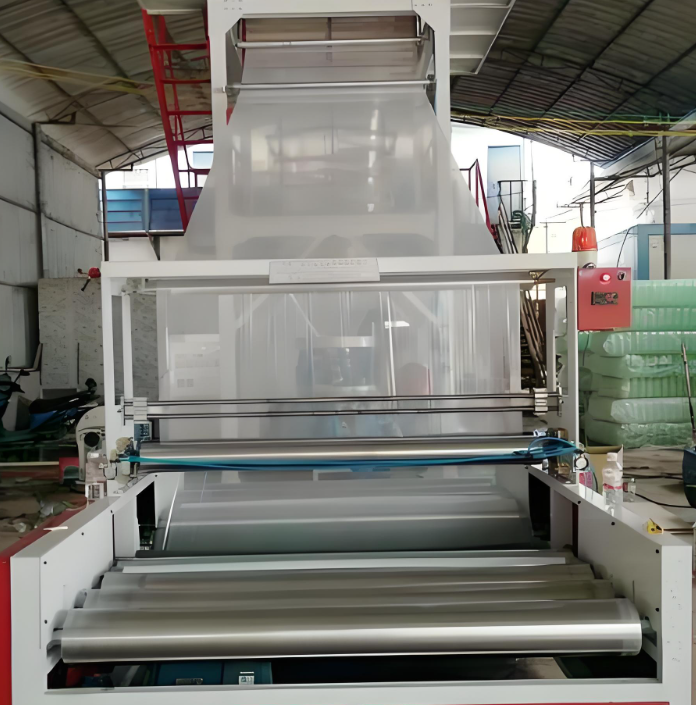

There are several advantages of the top blowing film blowing machine:1. Good film cooling effect: During the upward movement of the film bubble, the flow direction is opposite to the naturally rising hot air, forming "countercurrent cooling". Combined with the top cooling air ring, the film temperat

Plastic film blowing machines can be classified as follows:1. According to the type of raw materials: polyethylene (PE) film blowing machine, polypropylene (PP) film blowing machine, polyvinyl chloride (PVC) film blowing machine, polyamide (PA) film blowing machine, etc.2. According to the shape of

Plastic film blowing machine is a plastic processing equipment that heats and melts plastic particles and blows them into thin films. It is mainly used to produce packaging films made of PE, POF, PVC and other materials. It is widely used in food, medicine, agriculture and other fields.The core proc

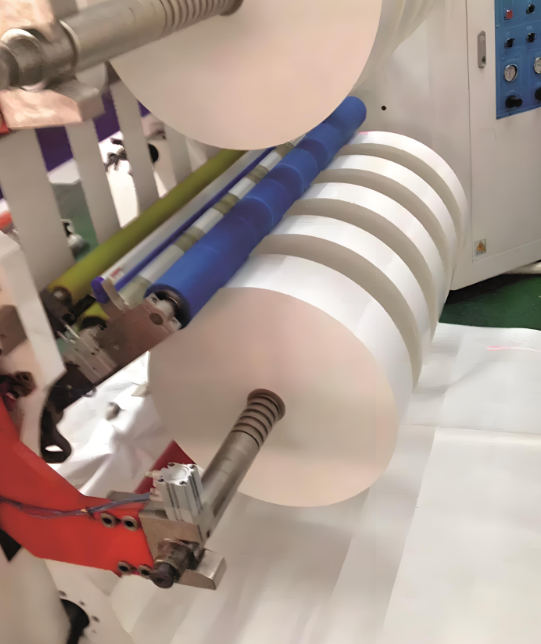

Semi-automatic slitting machine is a device used to slit wide rolls into specified narrow rolls. It requires manual assistance to complete some operations (such as loading, unloading, parameter adjustment, etc.). The degree of automation is between manual and fully automatic.Semi-automatic slitting

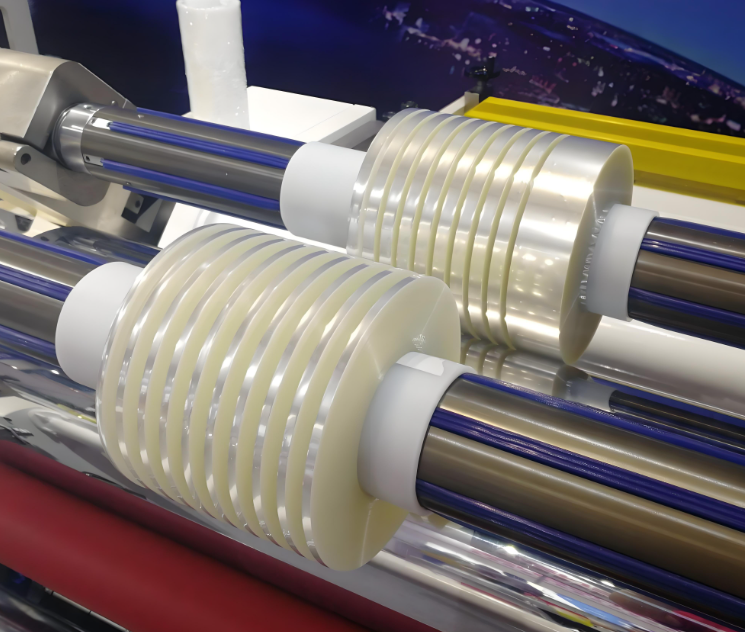

The fully automatic slitting machine is an automated mechanical equipment used to automatically slit wide roll materials (such as film, paper, metal foil, etc.) into narrow strips of roll materials with a set width.In the packaging industry, the fully automatic slitting machine is suitable for slitt

Manual slitting machine is a device that realizes material slitting through manual operation. It is mainly used to cut coils or sheets into required width/length.It is widely used in packaging, printing, textile, leather, film, paper and other industries to cut plastic film, paper, cloth, tape and o

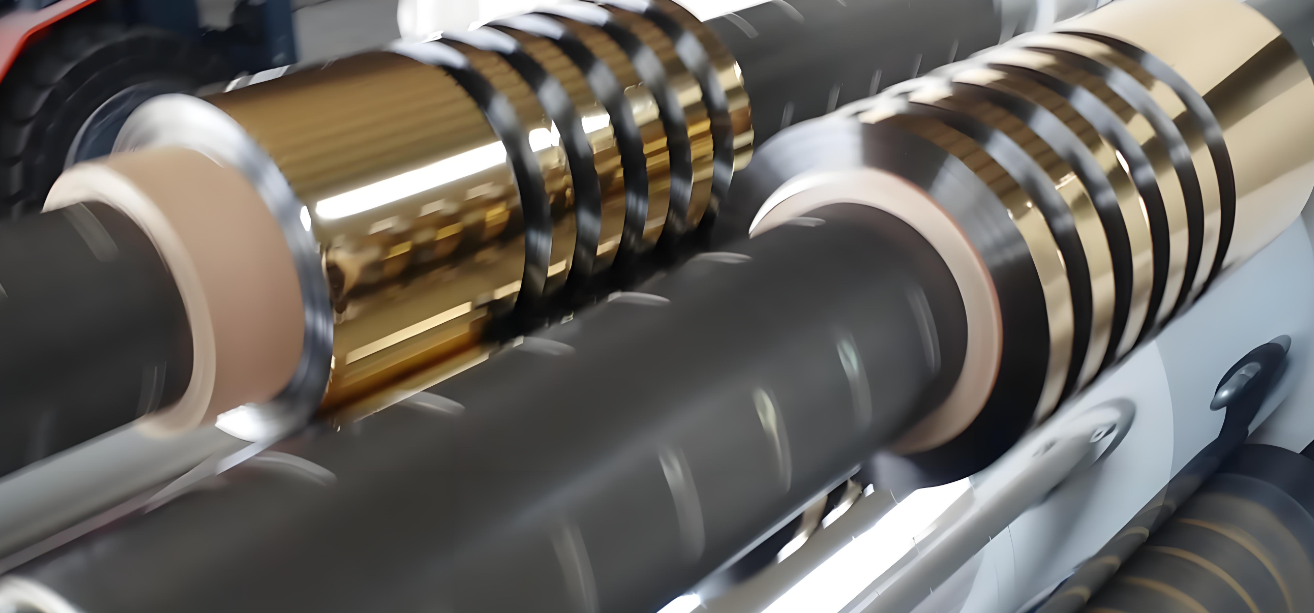

Surface winding and slitting machine is a device that cuts wide materials into narrow materials. It is widely used in the processing of thin materials such as paper, film, non-woven fabrics, etc.Its core function is to achieve efficient slitting and winding of materials through surface winding techn

The center coiling and slitting machine is widely evaluated in various material slitting scenarios, mainly in the fields of electronic materials, packaging materials, industrial supplies, etc.The following are specific application scenarios:1.Electronic Material ProcessingSuitable for slitting elect