| Availability: | |

|---|---|

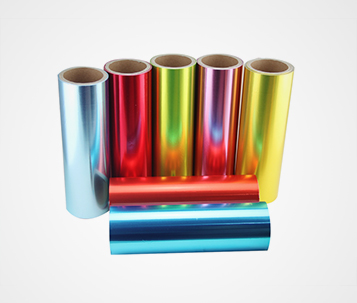

Branded Accessories

Product Parameter

Items | Details |

Applicable material | Roll materials such as plastic film and paper etc. |

Quantity of Color | 1-12 (can be customized) |

Max mechanical speed | 150-200m/min |

Material width | 850/1050/1250/1450/1650mm |

Registration precision | ≤±0.10mm |

Max unwind & rewind Dia. | Ф800,Ф1000mm |

Printing cylinder Dia. | Ф120mm-Ф300mm |

Dry method | Electricity,Steam,Thermal oil or Gas |

Product introduction

Gear drive roto gravure printing machine is a high quality and high cost performance product which designed by our company according to the market requirement. This machine is suitable for multicolor continuous printing.

There are many advantages of automatic rotogravure printing machine:

Seven motor and four floating roller automatic tension control system, shaft-less and pneumatic lock up, unwind and rewind automatically connect material, pneumatic air shaft, register by computer lengthways.

Reasonable structure, easy operation, quick printing speed, high accuracy, less waste and other advantages.

Imported famous brand spare parts ensure the machine high reliability and stability.

Product features

Gear drive rotogravure printing machine adopts an advanced seven-motor four-stage closed-loop tension control system, and the automatic tension change action program is controlled by Panasonic PLC and man-machine interface. Under high-speed working condition, it can automatically connect and change materials. The whole machine has an exquisite structure and beautiful appearance. It is suitable for printing on various film materials.

Here are its main characteristics:

I.Independent tower double-station rewinding and unwinding rack, length adjustable shaftless air cap device, fast replacement, safe and reliable, high-speed non-stop material change, automatic cutting.

II.Vertical and horizontal automatic color register and pre-register device to improve the register accuracy, The scraper movement is a double-axis movement type, independent motor control, the ink transfer roller transfers the ink device.

III.High energy-saving system with large air volume and high air pressure, multiple return air paths, and a cyclone layout on the entire surface.

IV.The tension control system of seven AC vector inverter motors controlled by imported PLC is adopted, and the main components are imported brands.

Applications

Our rotogravure printing machine can be applied to food packaging, drug packaging, daily chemical packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

PVDC | 35-60um |

PE | 30-100um |

OPP | 12-50um |

BOPP | 19-60um |

PET | 9-60um |

NY | 12-50um |

CPP | 20-60um |

Laminated film | 15-60um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

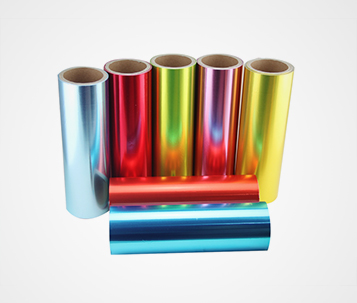

Branded Accessories

Product Parameter

Items | Details |

Applicable material | Roll materials such as plastic film and paper etc. |

Quantity of Color | 1-12 (can be customized) |

Max mechanical speed | 150-200m/min |

Material width | 850/1050/1250/1450/1650mm |

Registration precision | ≤±0.10mm |

Max unwind & rewind Dia. | Ф800,Ф1000mm |

Printing cylinder Dia. | Ф120mm-Ф300mm |

Dry method | Electricity,Steam,Thermal oil or Gas |

Product introduction

Gear drive roto gravure printing machine is a high quality and high cost performance product which designed by our company according to the market requirement. This machine is suitable for multicolor continuous printing.

There are many advantages of automatic rotogravure printing machine:

Seven motor and four floating roller automatic tension control system, shaft-less and pneumatic lock up, unwind and rewind automatically connect material, pneumatic air shaft, register by computer lengthways.

Reasonable structure, easy operation, quick printing speed, high accuracy, less waste and other advantages.

Imported famous brand spare parts ensure the machine high reliability and stability.

Product features

Gear drive rotogravure printing machine adopts an advanced seven-motor four-stage closed-loop tension control system, and the automatic tension change action program is controlled by Panasonic PLC and man-machine interface. Under high-speed working condition, it can automatically connect and change materials. The whole machine has an exquisite structure and beautiful appearance. It is suitable for printing on various film materials.

Here are its main characteristics:

I.Independent tower double-station rewinding and unwinding rack, length adjustable shaftless air cap device, fast replacement, safe and reliable, high-speed non-stop material change, automatic cutting.

II.Vertical and horizontal automatic color register and pre-register device to improve the register accuracy, The scraper movement is a double-axis movement type, independent motor control, the ink transfer roller transfers the ink device.

III.High energy-saving system with large air volume and high air pressure, multiple return air paths, and a cyclone layout on the entire surface.

IV.The tension control system of seven AC vector inverter motors controlled by imported PLC is adopted, and the main components are imported brands.

Applications

Our rotogravure printing machine can be applied to food packaging, drug packaging, daily chemical packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

PVDC | 35-60um |

PE | 30-100um |

OPP | 12-50um |

BOPP | 19-60um |

PET | 9-60um |

NY | 12-50um |

CPP | 20-60um |

Laminated film | 15-60um |

plastic bags

wipe packaging

laminated materials

food labels

paper cups

water labels

paper

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...