| Availability: | |

|---|---|

Branded Accessories

Product Parameter

Items | Details |

Printing Material | BOPP. PET, PVC. PE, NY |

Quantity of Color | 1-12 (can be customized) |

Max Mechanical Speed | 350m/min |

Color Register Accuracy | +-0.1mm |

Plate Cylinder | φ120-φ300mm |

Unwind/rewind Web Dia | φ600mm/φ800mm |

Machine Model | 850/1050/1250/1450/1650mm |

Product introduction

Electronic Line Shaft roto gravure printing machine is our company with Europe's high-end printing equipment and a research and development at home and abroad to meet the high-end market products.

There are many advantages of Electronic Line Shaft gravure printing machine:

The printing machine is a shaftless drive and gearless servo transmission system.

All printing operations are synchronized by the central controller.

It is fast in register, fast in speed, fast in lift-off, and has low pick-up scrap rate.

Its units are more flexible to use, shorten the printing preparation time and simplify the mechanical structure.

Product features

Els rotogravure printing machine uses direct-drive electronic shaft drive, printing unit servo motor directly combined with the printing roller, with digital, high-speed, intelligent and other advantages. Suitable for printing in all kinds of thin film materials.

Here are its main characteristics:

I.External disc type double-station rewinding and unwinding rack, strong stability,air shaft with safety chuck for loading and unloading rolls, automatic cutting when changing rolls, horizontal linear cutter for unwinding and rewinding, capable of front and back cutting, with rewinding and pressing roller device; ultrasonic roll diameter detection system.

II.The whole machine adopts high-precision servo drive without backlash, shaftless air top loading, vertical and horizontal automatic color registration and pre-registration device, direct pressure mechanism that does not change the material length, and ink transfer roller transfers the ink device, improve the registration, reducing scrap loss. Doctor movement is a double-axis movement type, quick-change type scraper, independent motor control; three-way adjustable box type scraper. Independent loading and ink supply integrated trolley.

III.Independent and efficient drying system with intelligent control, Forming the energy saving effect of large air volume and high air pressure, multiple return air paths, and a cyclone layout on the entire surface. Centralized touch screen control and monitoring of the working status of the whole machine, and has complete safety protection functions, It can intelligently identify the working state of the whole machine and judge the fault; The oven adopts the overall thermal insulation design, which can effectively reduce heat loss.

IV.Whole machine adopts imported servo motor tension control system, quantitative centralized lubrication system, Ensure the flexibility of the guide rollers at high speeds.

Applications

Our ELS roto gravure printing machine can be applied to food packaging, drug packaging, daily chemical packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

PVDC | 35-60um |

PE | 30-100um |

OPP | 12-50um |

BOPP | 19-60um |

PET | 9-60um |

NY | 12-50um |

CPP | 20-60um |

Laminated film | 15-60um |

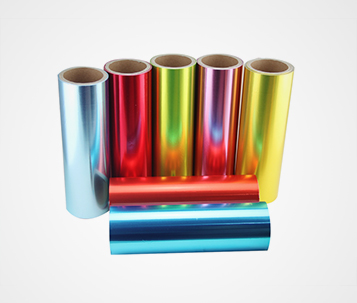

plastic bags

wipe packaging

laminated materials

food packaging

Yogurt Foil Cover

water labels

Pharmaceutical AL foil printing

food pouches

Factory & Workshop

Branded Accessories

Product Parameter

Items | Details |

Printing Material | BOPP. PET, PVC. PE, NY |

Quantity of Color | 1-12 (can be customized) |

Max Mechanical Speed | 350m/min |

Color Register Accuracy | +-0.1mm |

Plate Cylinder | φ120-φ300mm |

Unwind/rewind Web Dia | φ600mm/φ800mm |

Machine Model | 850/1050/1250/1450/1650mm |

Product introduction

Electronic Line Shaft roto gravure printing machine is our company with Europe's high-end printing equipment and a research and development at home and abroad to meet the high-end market products.

There are many advantages of Electronic Line Shaft gravure printing machine:

The printing machine is a shaftless drive and gearless servo transmission system.

All printing operations are synchronized by the central controller.

It is fast in register, fast in speed, fast in lift-off, and has low pick-up scrap rate.

Its units are more flexible to use, shorten the printing preparation time and simplify the mechanical structure.

Product features

Els rotogravure printing machine uses direct-drive electronic shaft drive, printing unit servo motor directly combined with the printing roller, with digital, high-speed, intelligent and other advantages. Suitable for printing in all kinds of thin film materials.

Here are its main characteristics:

I.External disc type double-station rewinding and unwinding rack, strong stability,air shaft with safety chuck for loading and unloading rolls, automatic cutting when changing rolls, horizontal linear cutter for unwinding and rewinding, capable of front and back cutting, with rewinding and pressing roller device; ultrasonic roll diameter detection system.

II.The whole machine adopts high-precision servo drive without backlash, shaftless air top loading, vertical and horizontal automatic color registration and pre-registration device, direct pressure mechanism that does not change the material length, and ink transfer roller transfers the ink device, improve the registration, reducing scrap loss. Doctor movement is a double-axis movement type, quick-change type scraper, independent motor control; three-way adjustable box type scraper. Independent loading and ink supply integrated trolley.

III.Independent and efficient drying system with intelligent control, Forming the energy saving effect of large air volume and high air pressure, multiple return air paths, and a cyclone layout on the entire surface. Centralized touch screen control and monitoring of the working status of the whole machine, and has complete safety protection functions, It can intelligently identify the working state of the whole machine and judge the fault; The oven adopts the overall thermal insulation design, which can effectively reduce heat loss.

IV.Whole machine adopts imported servo motor tension control system, quantitative centralized lubrication system, Ensure the flexibility of the guide rollers at high speeds.

Applications

Our ELS roto gravure printing machine can be applied to food packaging, drug packaging, daily chemical packaging and so on. There are suitable materials and their acceptable thickness.

Materials | Thickness |

PVDC | 35-60um |

PE | 30-100um |

OPP | 12-50um |

BOPP | 19-60um |

PET | 9-60um |

NY | 12-50um |

CPP | 20-60um |

Laminated film | 15-60um |

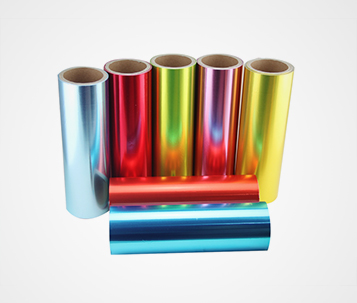

plastic bags

wipe packaging

laminated materials

food packaging

Yogurt Foil Cover

water labels

Pharmaceutical AL foil printing

food pouches

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...