| Availability: | |

|---|---|

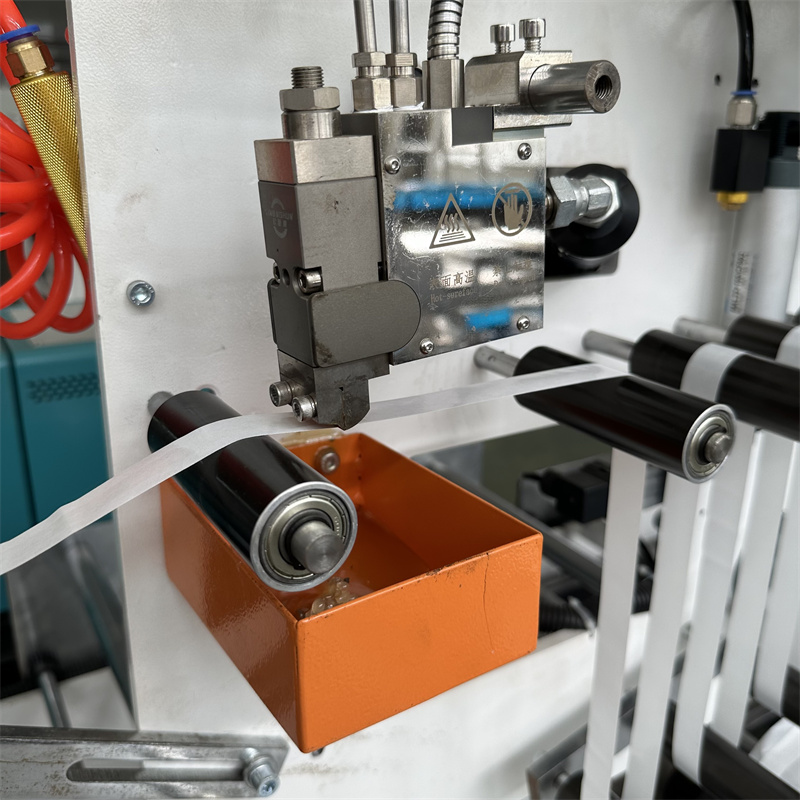

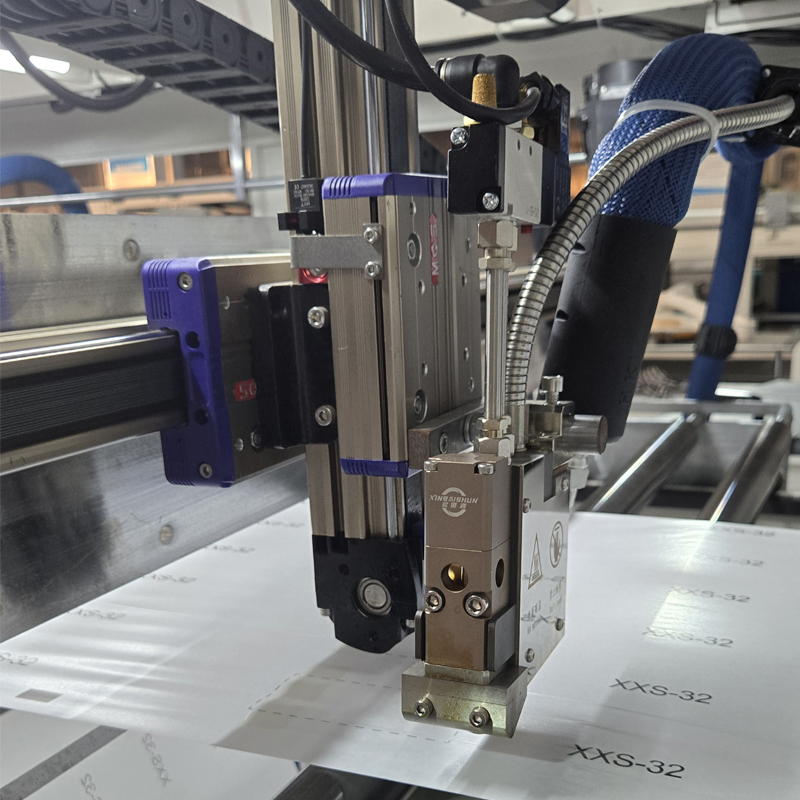

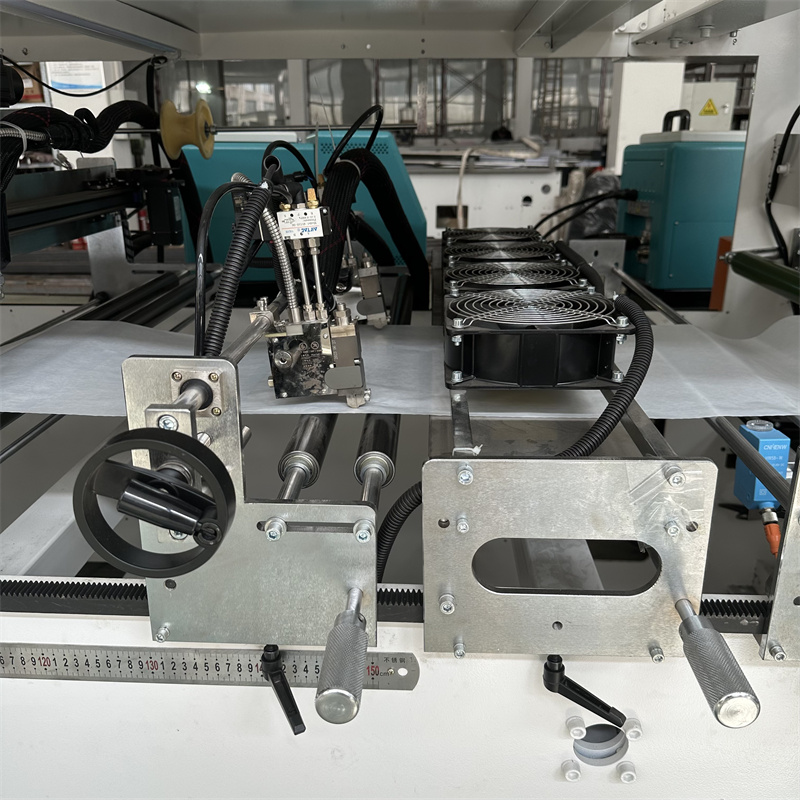

Details of machine

Touch screen

Two layers paper glued together

Removable glue box

Second unwinding

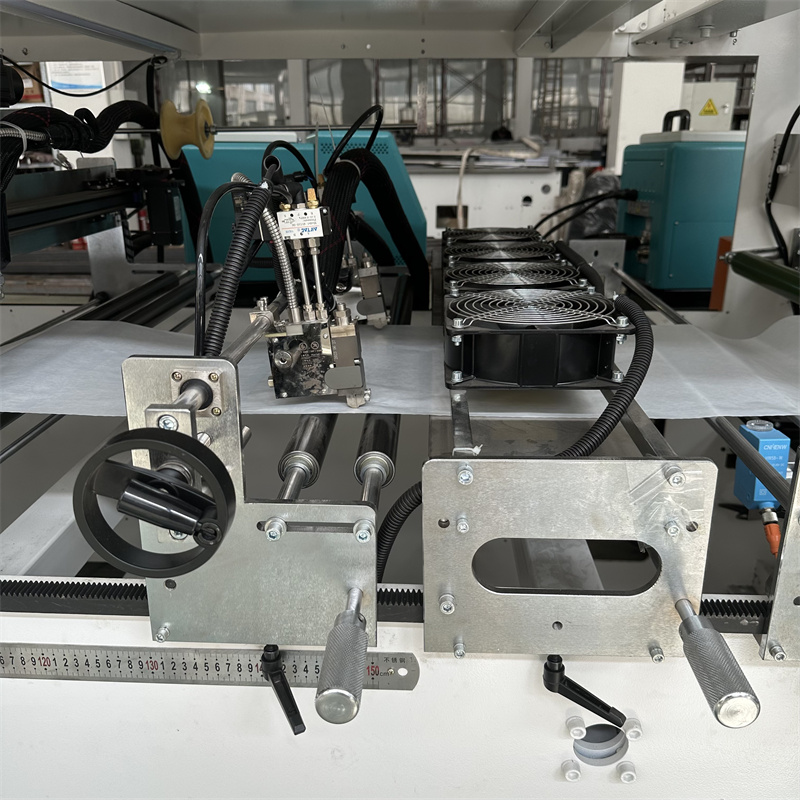

Repeat pressing

Traction

Mitsubishi PLC and Servo

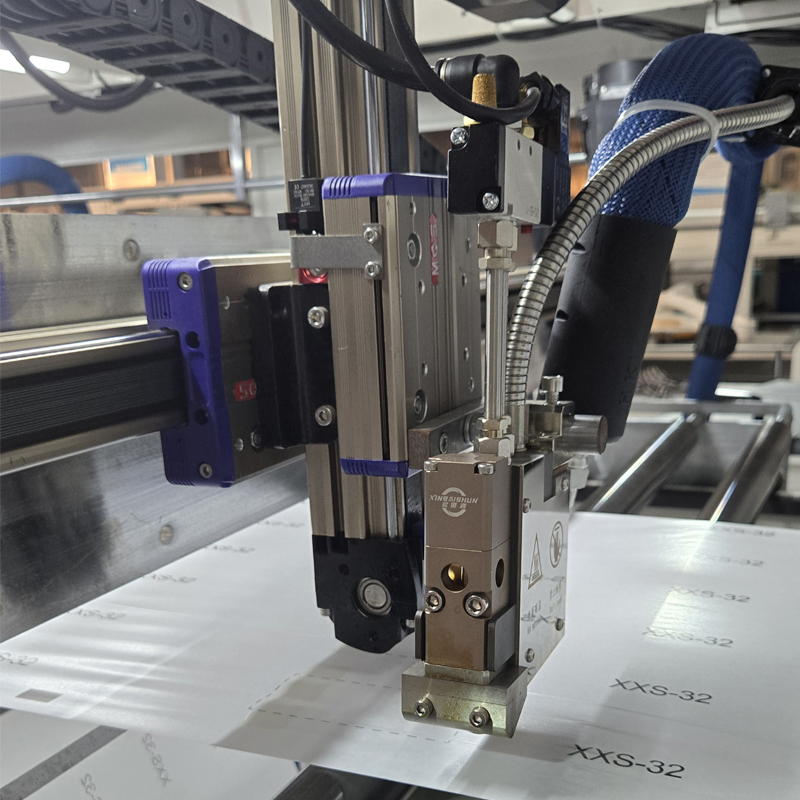

Apply removable glue on release paper

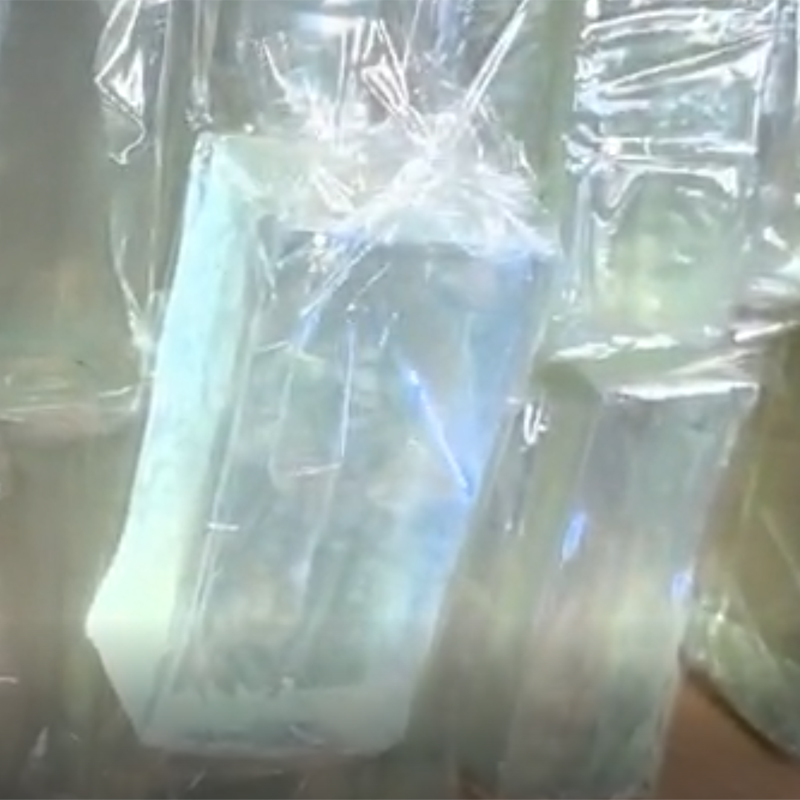

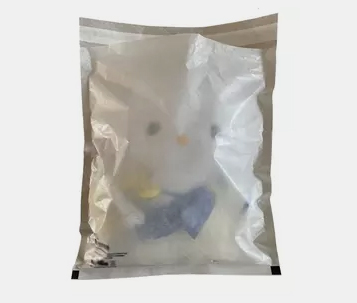

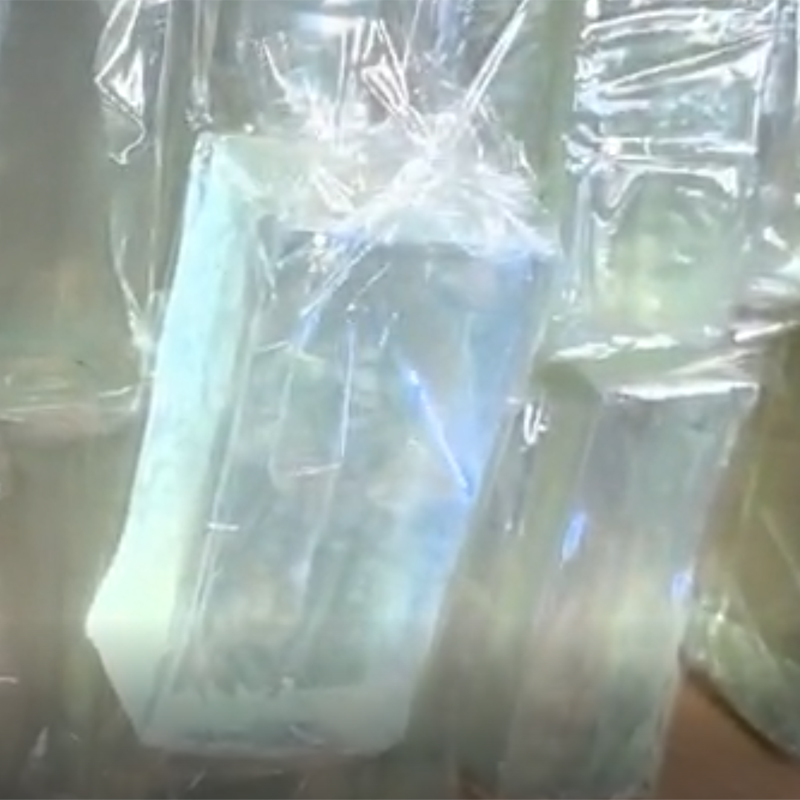

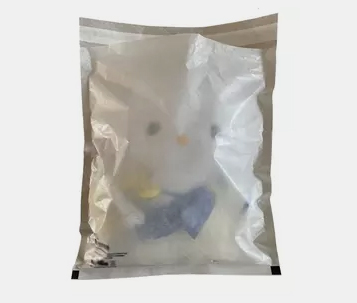

Bag sample display

Bag Sample

Final bag

First unwinding

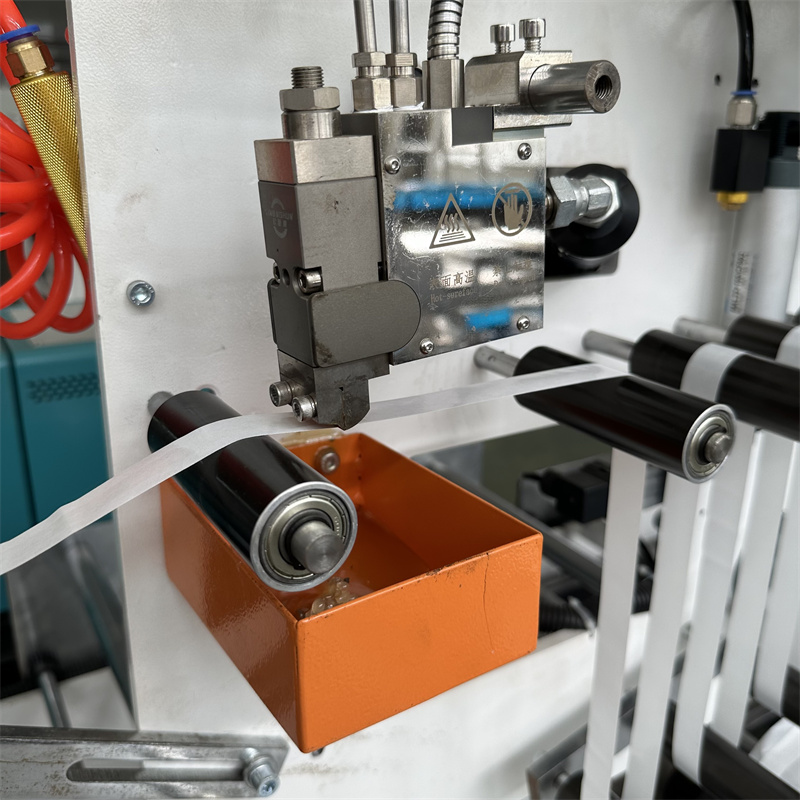

Hot melt glue box(standard 3 sets)

Final product bag

Top and bottom paper

Two side glue heads

Removable gluing with release paper

Side glue heads

Bag collecting table

Bottom glue head

Glassine paper

Heating and Repeat pressing

Hot melt glue

Logo of machine

Opitonal 4th side glue head

Removable glue head

Removable glue

One bottom glue head

Branded Accessories

Technical specification

Detail | Model 900 |

Unwinding width | 850mm |

Unwinding diameter | 700mm |

Mechanical speed | 0≤80m |

Capacity | 60-120pcs/min (when produce small bags, it reaches 120pcs/min) |

Machine Weight | 2000kg |

Power supply voltage | 220V/380V |

Unwinding Part

1: Load with axis, equipped with 3” convex button air rising axis | 2 sets |

2: Unwind with 10kg magnetic powder brake produced by lanling from China | 2 sets |

3: Pushed photoelectric automatic deflection correction device | 2 sets |

4: Unwinding tension is automatic constant tension control | 1 set |

Traction part

1: Unloading rubber roller ¢80×950 | 2 sets |

2: Unloading motor is 0.75 frequency motor | 2 sets |

3: Unloading pressure roller is adjusted by air pressure | 2 sets |

Material Storage Part

1: The material storage is swing arm type | 2 sets |

2: The material storage tension is adjusted by air pressure. | 2 sets |

3: Storage cylinder on the left and right | 2 sets |

Gluing and bottom gusset inserting function part

1: Longitudinal Z-axis servo motor gluing | 2 set |

2: Horizontal X-axis servo motor gluing | 2 sets |

3: Gluing can be moved left and right | 2 sets |

4: Bottom gluing can be moved left and right | 2 sets |

5: The bottom feeding is a variable frequency motor feeding | 1 set |

6: The bottom feeding shaft is air shaft | 1 set |

7: The bottom unwinding tension is a constant tension | 1 set |

8: The bottom forming is a triangular folding template | 1 set |

Back Traction Part

1: Rear traction rubber roller is ¢80×850 | 1 set |

2: The main traction motor is 2.0 servo motor | 1 set |

3: Anti photoelectric positioning tracking | 1 set |

Down Traction Part

1: Traction rubber roller is ¢80×850 | 1 set |

2: Traction motor is 2.0 servo motor | 1 set |

3: Downward reflective photoelectric positioning tracking | 1 set |

Functional Part

1: Hot knife can be moved | 2 sets |

2: Front photoelectric positioning and tracking | 1 set |

3: Moveable centrifugal film scraper | 1 set |

4: Centrifugal film unwind with 0.55 motor unwind | 1 set |

5: Centrifugal film storage controlled by air pressure of swing Arm | 1 set |

6 : The swing arm air pressure is regulated by a precision pressure regulating valve | 2 sets |

Slitting front traction part

1: Traction rubber roller is ¢80×950 | 1 set |

2: Traction motor is 2.0 Mitsubishi servo motor | 1 set |

3: Slitting waste edge is air knife type adjustable | 1 set |

4: Waste edge is blown out in the form of air blowing | 1 set |

Cutting Knife Part

1: Cutting knife slide up and down by the guide roller | 2 sets |

2: Cutting knife is with air blowing function | 1 set |

Main Control Part

1: Mainly controlled by PLC touch screen | 1 set |

2: Main motor is 1.5kw |

Collecting Bag Part

1: Motor is 0.55kw | 1 set |

2: Conveyor belt is PU | 1 set |

3: Conveying speed can be adjusted freely | 1 set |

4: Conveyor baffle | 1 set |

You can change the accessory brand according to your needs.

Applications

Because of the three advantages of high temperature resistance, moisture resistance and oil resistance, more and more people choose to use glassine paper, and we can use it in different occasions.

Fully automatic glassine paper bag making machine can be applied to food packaging, clothes packaging and so on.

pouches with gusset

clothes

food

toys

collectors

tableware

cosmetics

medicine

Factory & Workshop

Details of machine

Touch screen

Two layers paper glued together

Removable glue box

Second unwinding

Repeat pressing

Traction

Mitsubishi PLC and Servo

Apply removable glue on release paper

Bag sample display

Bag Sample

Final bag

First unwinding

Hot melt glue box(standard 3 sets)

Final product bag

Top and bottom paper

Two side glue heads

Removable gluing with release paper

Side glue heads

Bag collecting table

Bottom glue head

Glassine paper

Heating and Repeat pressing

Hot melt glue

Logo of machine

Opitonal 4th side glue head

Removable glue head

Removable glue

One bottom glue head

Branded Accessories

Technical specification

Detail | Model 900 |

Unwinding width | 850mm |

Unwinding diameter | 700mm |

Mechanical speed | 0≤80m |

Capacity | 60-120pcs/min (when produce small bags, it reaches 120pcs/min) |

Machine Weight | 2000kg |

Power supply voltage | 220V/380V |

Unwinding Part

1: Load with axis, equipped with 3” convex button air rising axis | 2 sets |

2: Unwind with 10kg magnetic powder brake produced by lanling from China | 2 sets |

3: Pushed photoelectric automatic deflection correction device | 2 sets |

4: Unwinding tension is automatic constant tension control | 1 set |

Traction part

1: Unloading rubber roller ¢80×950 | 2 sets |

2: Unloading motor is 0.75 frequency motor | 2 sets |

3: Unloading pressure roller is adjusted by air pressure | 2 sets |

Material Storage Part

1: The material storage is swing arm type | 2 sets |

2: The material storage tension is adjusted by air pressure. | 2 sets |

3: Storage cylinder on the left and right | 2 sets |

Gluing and bottom gusset inserting function part

1: Longitudinal Z-axis servo motor gluing | 2 set |

2: Horizontal X-axis servo motor gluing | 2 sets |

3: Gluing can be moved left and right | 2 sets |

4: Bottom gluing can be moved left and right | 2 sets |

5: The bottom feeding is a variable frequency motor feeding | 1 set |

6: The bottom feeding shaft is air shaft | 1 set |

7: The bottom unwinding tension is a constant tension | 1 set |

8: The bottom forming is a triangular folding template | 1 set |

Back Traction Part

1: Rear traction rubber roller is ¢80×850 | 1 set |

2: The main traction motor is 2.0 servo motor | 1 set |

3: Anti photoelectric positioning tracking | 1 set |

Down Traction Part

1: Traction rubber roller is ¢80×850 | 1 set |

2: Traction motor is 2.0 servo motor | 1 set |

3: Downward reflective photoelectric positioning tracking | 1 set |

Functional Part

1: Hot knife can be moved | 2 sets |

2: Front photoelectric positioning and tracking | 1 set |

3: Moveable centrifugal film scraper | 1 set |

4: Centrifugal film unwind with 0.55 motor unwind | 1 set |

5: Centrifugal film storage controlled by air pressure of swing Arm | 1 set |

6 : The swing arm air pressure is regulated by a precision pressure regulating valve | 2 sets |

Slitting front traction part

1: Traction rubber roller is ¢80×950 | 1 set |

2: Traction motor is 2.0 Mitsubishi servo motor | 1 set |

3: Slitting waste edge is air knife type adjustable | 1 set |

4: Waste edge is blown out in the form of air blowing | 1 set |

Cutting Knife Part

1: Cutting knife slide up and down by the guide roller | 2 sets |

2: Cutting knife is with air blowing function | 1 set |

Main Control Part

1: Mainly controlled by PLC touch screen | 1 set |

2: Main motor is 1.5kw |

Collecting Bag Part

1: Motor is 0.55kw | 1 set |

2: Conveyor belt is PU | 1 set |

3: Conveying speed can be adjusted freely | 1 set |

4: Conveyor baffle | 1 set |

You can change the accessory brand according to your needs.

Applications

Because of the three advantages of high temperature resistance, moisture resistance and oil resistance, more and more people choose to use glassine paper, and we can use it in different occasions.

Fully automatic glassine paper bag making machine can be applied to food packaging, clothes packaging and so on.

pouches with gusset

clothes

food

toys

collectors

tableware

cosmetics

medicine

Factory & Workshop

As a global supplier in the plastic bag making equipment and flexible packaging and metal packaging equipment, KingPac covers a plant area of 10000M2 and 80+ employees, with annual production capacity of...